|

|

|

|

| Round Vibratory Finishing Machines |

Round Vibratory Finishing Machines are specially designed for processing of all types of components, from high gloss polishing to heave deburring, radiusing, chamfering, grinding, descaling, degreasing, washing...

- Compact design.

- High abrasive efficiency, good surface finishing result.

- Heavy-duty electric vibration motor.

- Adjustable vibration control.

- High durable hot-poured polyurethane lined processing bowl to reduce the collide and prolong processing bowl working life.

|

| |

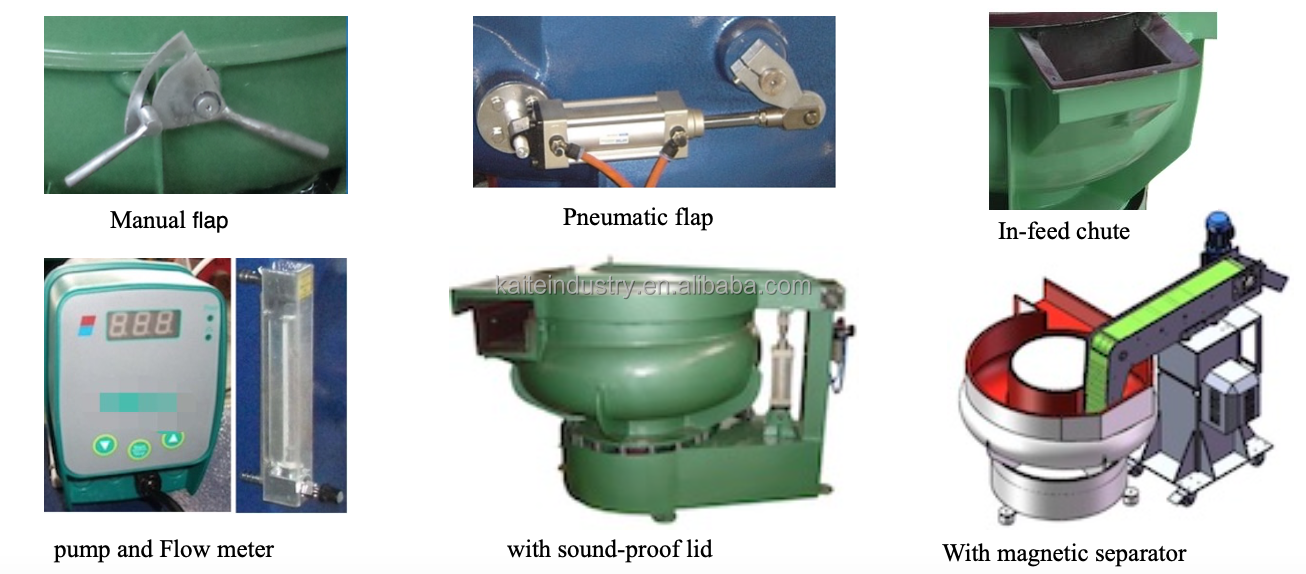

LZGS / LZGC with an integrated screening system consisting of manually (standard option) or pneumatically activated separation flap and a built-in separation screen.

Manually (standard option) or pneumatically activated separate flap for automatic separation, media and components are delivered over the separation screen and the media returns through the screen to the bowl and components discharge to a collect bin or secondary operation. This series machines are suited for the processing of high production, small components, or flat, lightweight parts which easy stick together. They are also suitable for steel ball burnishing processing.

- Changeable separation unit.

- Extra long screening zone? Easy separation of flat parts

- Option Variable speed controller panel with timer and controlled separation flap for automation.

- LZGC series processing bowl features a spiral-bottom helical geometry walls allow a damage-free processing of delicate components and preventing flat, thin parts from sticking together.

- LZGS series processing bowl features flat bottom with a built in spiral ramp for processing of delicate parts

- LZGS Optional side mounted parts in-feed chute facilitates integration into automatic manufacturing processes.

|

| |

LZGS |

Model |

Capacity (L) |

PU (mm) |

Power (KW) |

Dimensions

LxWxH (mm) |

Weight (KG) |

|

LZGS100 |

100 |

20 |

1.5 |

1300x1150x860 |

340 |

*LZGS100Z |

100 |

20 |

2.2 |

1300x1150x860 |

340 |

LZGS150 |

150 |

20 |

2.2 |

1250x1200x1020 |

360 |

LZGS200 |

200 |

20 |

3.0 |

1200x1200x1100 |

650 |

LZGS300 |

270 |

22 |

3.7 |

1400x1350x1000 |

650 |

*LZGS300Z |

270 |

22 |

5.0 |

1400x1350x1000 |

650 |

LZGS400 |

480 |

24 |

5.0 |

1480x1430x1100 |

780 |

LZGS600 |

660 |

26 |

5.5 |

2000x1800x1350 |

1400 |

*LZGS600Z |

660 |

26 |

7.5 |

2000x1800x1350 |

1400 |

LZGS900 |

900 |

26 |

9.0 |

2160x2153x1100 |

2200 |

* |

suitable for steel ball burnishing |

|

LZGC |

Model |

Capacity

(L) |

PU

(mm) |

Power

(KW) |

Dimensions

LxWxH (mm) |

Weight

(KG) |

|

LZGC100 |

100 |

20 |

1.5 |

1170x1100x950 |

320 |

*LZGC100Z |

100 |

20 |

2.2 |

1170x1100x950 |

320 |

LZGC200 |

200 |

20 |

3.0 |

1310x1150x950 |

400 |

LZGC300 |

260 |

22 |

3.7 |

1480x1330x1050 |

650 |

*LZGC300Z |

260 |

22 |

5.0 |

1480x1330x1050 |

650 |

LZGC600 |

580 |

26 |

5.5 |

2000x1800x1350 |

1400 |

*LZCC600Z |

580 |

26 |

7.5 |

2000x1800x1350 |

1400 |

LZGC900 |

900 |

26 |

9.0 |

2200x2300x1550 |

2470 |

* |

suitable for steel ball burnishing |

|

|

Options:

- Variable frequency drive speed controller control for automatic operation.

- In-feed chute (only for LZGS series) for connection with other machinery for automatic processing line.

- Pneumatic operated separation flap for automatic operation.

- Sound-proof lid to reduce the noise

- Compound metering system

|

| |

|

| |

PLZG / PLZGC (with cured wall) without integrated screening system, features flat-bottom, for processing a wide range of components from small, middle, delicate parts to large marble slabs, which easy damaged by dam and separation screen, or for a variety of parts of different sizes and batches, where automatic unloading does not have any particular advantage.

|

PLZG |

Model |

Capacity

(L) |

Power

(KW) |

Dimensions

LxWxH (mm) |

Weight

(KG) |

|

PLZG25 |

25 |

0.5 |

600 x 600 x 800 |

85 |

PLZG50 |

50 |

1.1 |

760 x 760 x 900 |

110 |

PLZG80 |

80 |

1.1 |

760 x 760 x 900 |

100 |

PLZG100 |

100 |

1.5 |

1050x1050x950 |

285 |

*PLZG100Z |

100 |

2.2 |

1050x1050x950 |

285 |

PLZG200 |

220 |

3.0 |

1200x1200x1000 |

400 |

PLZG300 |

260 |

3.7 |

1320x1320x930 |

600 |

*PLZG300Z |

260 |

5.0 |

1320x1320x930 |

600 |

PLZG400 |

400 |

5.0 |

1450x1450x1030 |

730 |

PLZG480 |

480 |

5.0 |

1430x1430x1100 |

730 |

PLZG600 |

660 |

5.5 |

1800x1800x1220 |

1300 |

*PLZG600Z |

660 |

7.5 |

1800x1800x1220 |

1300 |

PLZG800 |

780 |

7.0 |

1800x1800x1220 |

1300 |

|

PLZG900 |

900 |

7.0 |

1900x1900x1450 |

2200 |

PLZG1200 |

1200 |

11.0 |

2120x2120x1500 |

2200 |

PLZG1500 |

1500 |

14.0 |

2120x2120x1550 |

2400 |

PLZG2500 |

2500 |

18.5 |

2320x2320x1570 |

3000 |

* |

suitable for steel ball burnishing |

|

PLZGC |

|

Model |

Capacity

(L) |

Power

(KW) |

Dimensions

L x W x H (mm) |

Weight

(KG) |

|

PLZGC30 |

30 |

0.5 |

600 x 600 x 810 |

100 |

PLZGC80 |

80 |

1.1 |

760 x 760 x 920 |

100 |

PLZGC100 |

100 |

1.5 |

1100x1100x950 |

285 |

*PLZGC100Z |

100 |

2.2 |

1100x1100x950 |

285 |

PLZGC200 |

200 |

3.0 |

1200x1200x1050 |

560 |

PLZGC300 |

300 |

3.7 |

1200x1200x1000 |

560 |

|

PLZGC300Z |

300 |

5.0 |

1200x1200x1000 |

560 |

PLZGC350 |

345 |

5.0 |

1450x1450x1030 |

600 |

PLZGC600 |

600 |

5.5 |

1800x1800x1220 |

1080 |

PLZGC600Z |

600 |

7.5 |

1800x1800x1220 |

1080 |

PLZGC900 |

900 |

7.0 |

1900x1900x1450 |

1800 |

PLZGC1200 |

1200 |

11.0 |

2120x2120x1500 |

2400 |

* |

suitable for steel ball burnishing |

|

Option:

- Variable frequency drive speed controller control for automatic operation.

- Sound-proof lid to reduce noise.

- Compound metering system.

|

|

| Helical tubular vibratory finishing machine |

Helical tubular vibratory finishing machine is suitable for surface finishing of large quantities of medium or

small size parts.

Features:

- Integrated with entrance chute and exit chute, make it easy to be combined with other equipments into an automatic production line.

- Helical tubularlined PU, having long work life.

- Length of helical tubular up to 18 meter, with high conveying speed, can greatly improve processing capability.

- Workpieces forced flow up and down inside the tubular, which makes the machine having heavy grinding performance.

- Can process delicate workpieces without scratching on the surfaces.

- Semitransparent helical tubular make it easy to observe the workpieces flowing state inside the tubular.

- VFD speed control for more processing options.

- Processing period adjustable.

- Compact design saving much more space.

- Helical tubular can be disassembled and cleaned.

Model |

LZGHT170 |

|

Capacity |

155L |

Motor |

5.5KW/1480rpm |

Loading height |

1210mm |

Unloading height |

1080mm |

Helical tubular diameter |

105mm |

Dimesion |

1453 x1400 x 1286mm |

Weight |

1200kg |

| Option: |

Compound pump + water flowmeter |

|

| |

|

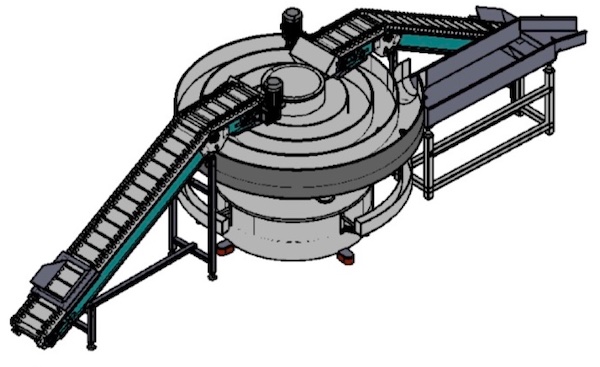

| Continuous Long Spiral Channel Vibratory Finishing Machine |

Continuous Long Spiral Channel Vibratory Finishing Machine is suitable for continuous-feed or batch surface processing ofdifferent sizes of stampings, castings, forgings and machined parts.It can carry out from heavy deburring, radiusing, chamfering, grinding, descaling, washing to high gloss polishing.

It has a very long processing channel, can finishing processing in on cycle in about 8-20 minutes.It mainly consists of vibratory finishing machine, part/media separate system, media return system, media return conveyor systempart loading conveyor system,. It can be can be easily integrated into any production line.

Features:

- Integrated with part loading convey system and part/media separate system, make it easy to be combined with other equipments into an automatic production line.

- Processing channel lined PU, having long work life.

- Length processing channel, with high conveying speed, can greatly improve processing capability.

- Can process delicate workpieces without part-on-part contact

- VFD speed control for more processing options.

- Processing period adjustable.

- PLC control for easy setting and operating.

Model |

LZGLC800 |

|

Capacity |

780L |

Vibratory Motor |

11KW/1460rpm |

Separator motor |

0.25KW x 2 |

Media returnmotor |

0.12KW |

Media conveyor motor |

1.1KW, 0.64m/s |

Part loading conveyor motor |

0.55KW, 0.238m/s |

Part discharge height |

945mm |

Dimesion |

7050 x2400 x 1960mm |

|

| |

|

|